PROGRESSIVE COMPONENTS

Our Services

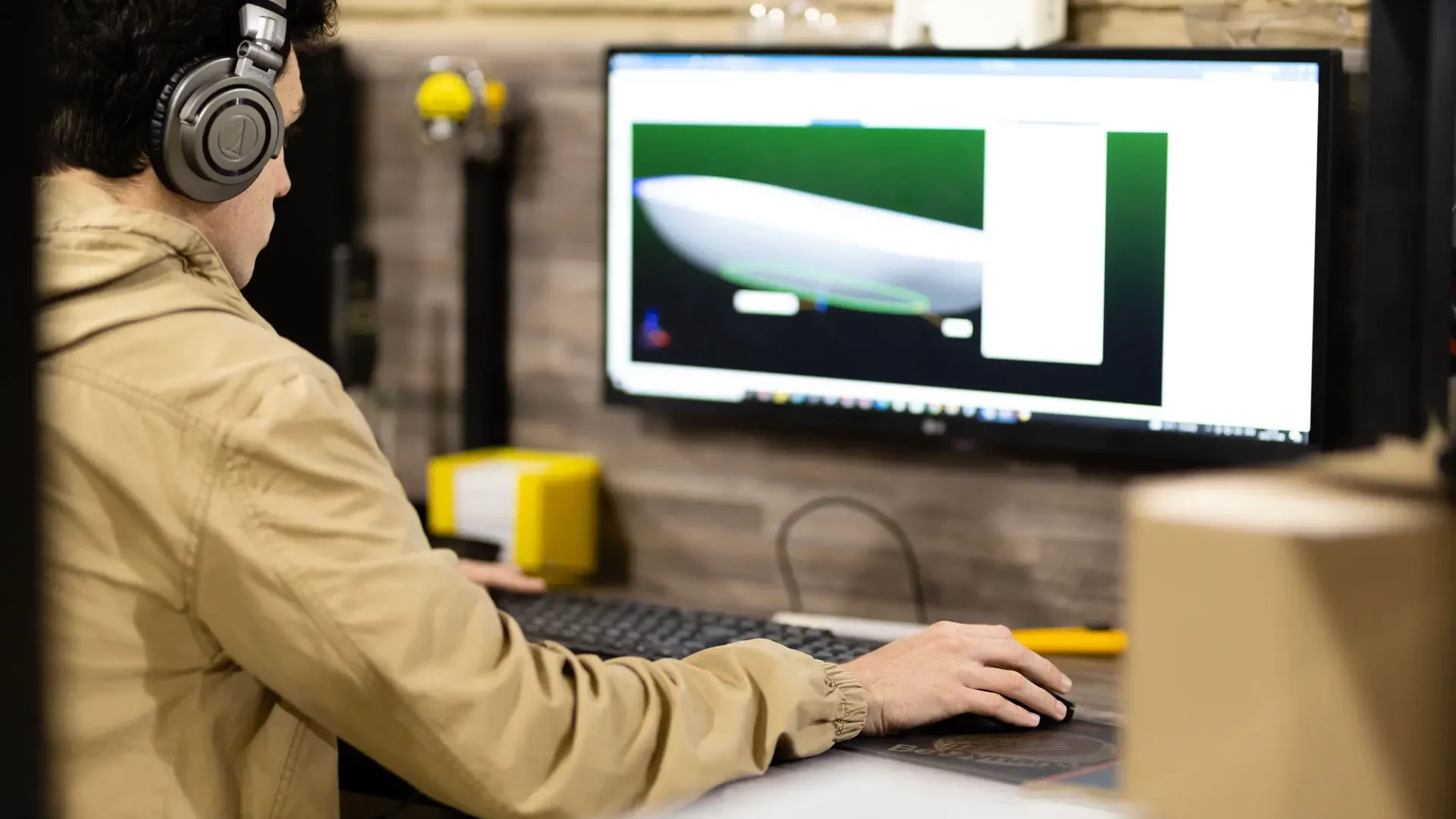

Design & Development

3D Printing

Mould Design

Mould Manufacturing

At Progressive Components our quality workmanship ensures repeat business.

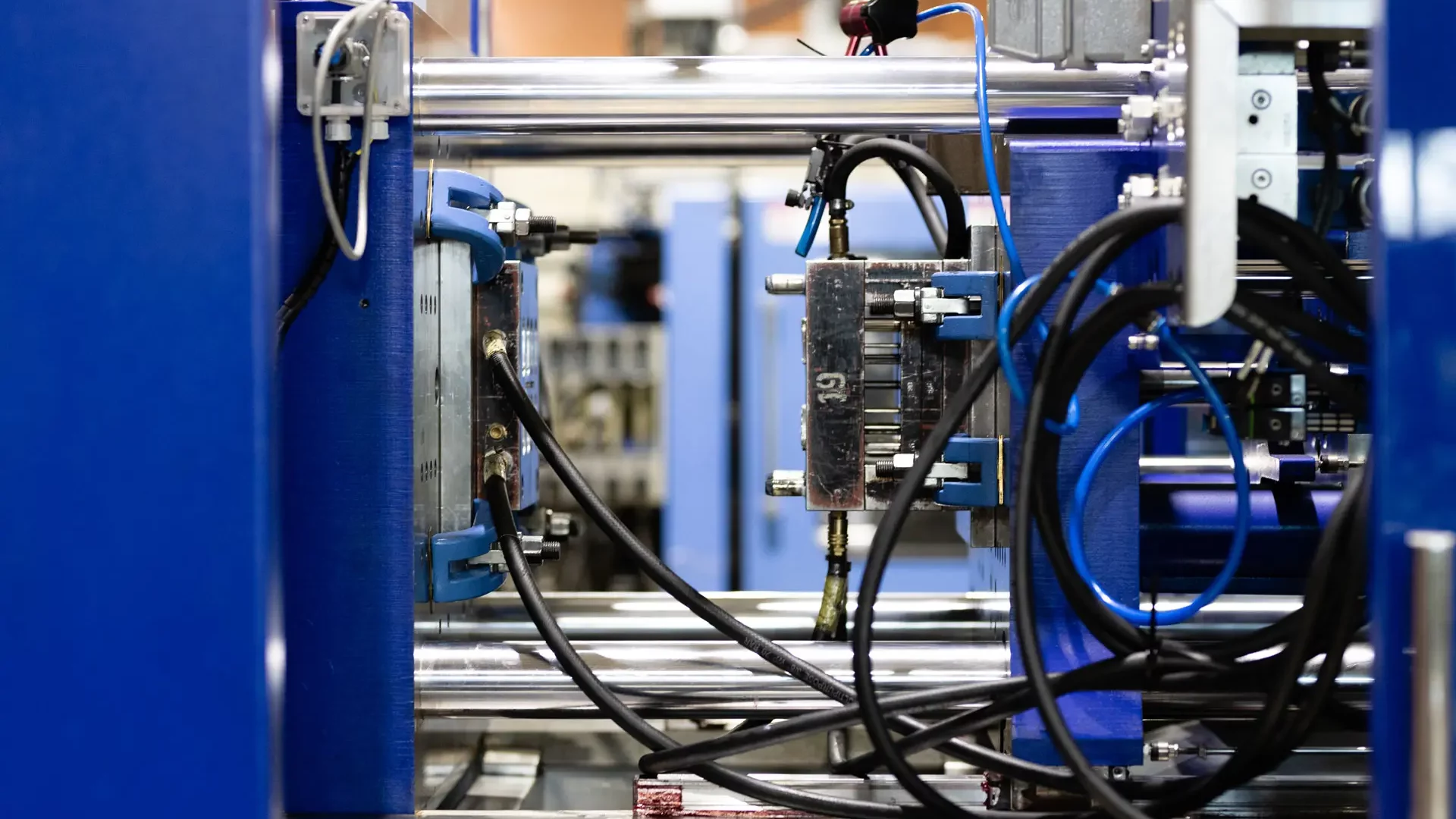

Components are run in various materials such as ABS, polycarbonate, nylon, glass-filled nylon, styrene, acrylic, polypropylene, monprene, neoprene and polyurethane, to meet customer and regulatory requirements. With our years of experience we are able to best advise on which material is suitable for each job. All tooling is cooled via water chillers ensuring that constant tool temperatures are maintained.

The majority of our customers require virgin materials for their products however, in line with the current sustainable mind-set, recycled materials are utilized where possible. All waste materials from our factory are collected by the respective recycling collectors.

Precision Engineering employs exacting design, crafting components with precise measurements. Its significance is crucial, especially in industries where even minor deviations lead to performance issues. Reliant on advanced machinery like CNC, Milling, and Laser Cutters, precision engineering ensures precise outcomes in sectors such as aerospace, automotive, and medical devices.

Fabrication processes produce diverse outcomes based on industries, materials, and project goals. Many individuals, businesses, and organizations may need fabrication services across different sectors. From manufacturing to artistic projects – fabrication turns ideas into reality.

Quick turn-around time

Global Reach

High Quality Materials

Industry Leading Machinery

Machine Simulations

What we stand for

Why Choose Us

Our machinery

In the Factory

In the Tool Room

5-Axis CNC Mill (Doosan DNM 350)

3-Axis CNC Mills

Our machinery

Fabrication

Laser Cutting

Bending

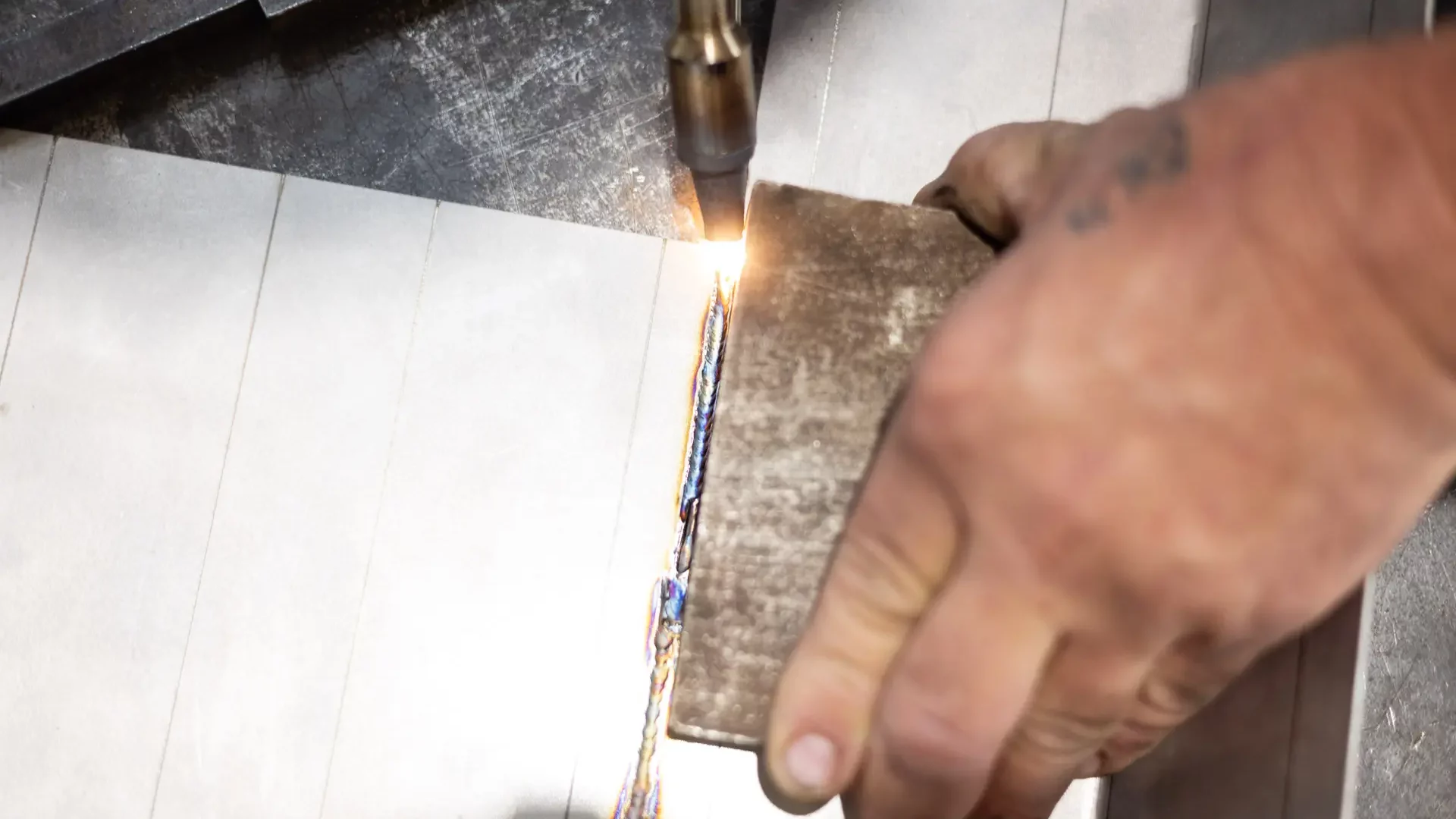

Welding

Industries we Serve

1.

Contact Us

Firstly, we need to know what you are looking for. Share your ideas or product concept as specifically as possible. Everything discussed is fully confidential.

2.

Conceptualisation

Firstly, we need to know what you are looking for. Share your ideas or product concept as specifically as possible. Everything discussed is fully confidential.

3.

Product Prototyping

Where necessary and on request, we can 3D Print a prototype of your design. This can ultimately save you time & money in the future ensuring the concept product will fit your requirements.

4.

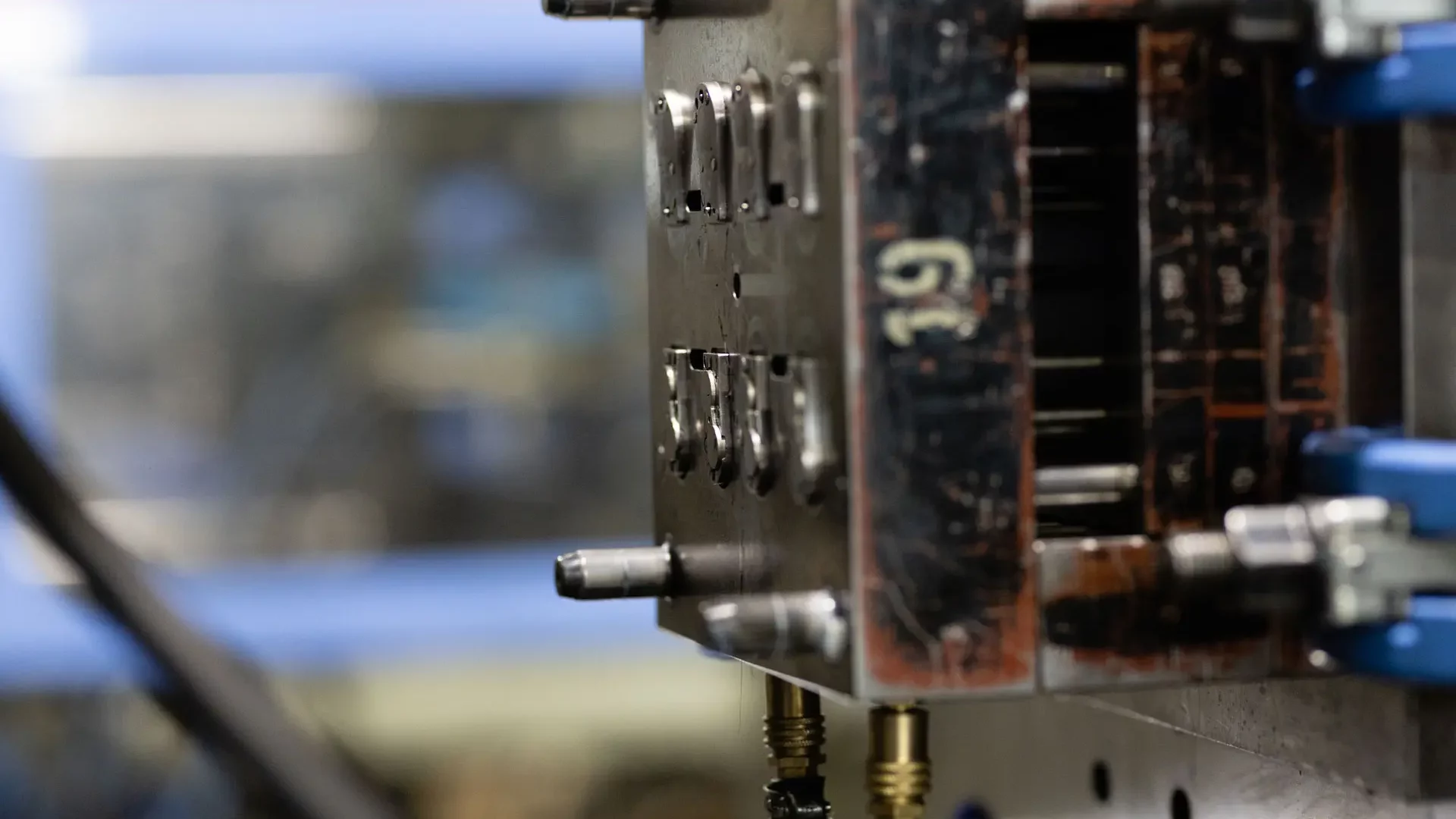

Mould Development

Once the design is approved, tooling will begin. There are many stages in the tooling processes, and this will be the most time consuming part of the project. Patience is key as rushed tools can cause long delays in production time. Our Toolmakers take the utmost pride and care when creating moulds. They ensure the finished mould will produce a satisfactory end product once it starts production.

5.

Source Materials

With our database and knowledge of raw materials and suppliers, we are able to source the best material for your final product. Materials are chosen based on the intended use of the component.

6.

Manufacture

Once the tool is complete, production will start with a small run of samples to ensure the materials used are suitable for the intended purpose and the tool is performing flawlessly.

7.

Quality Check

All components undergo strict quality control throughout the production process, from raw material preparation, machine setting and final product.

8.

Shipment

All products are boxed and either delivered by us locally or shipped to customers with a reliable logistics company.